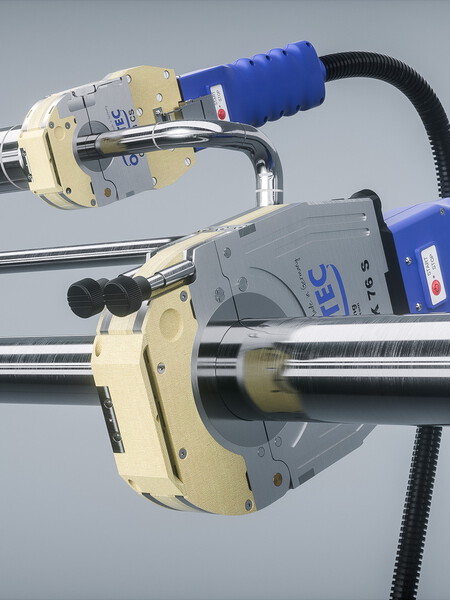

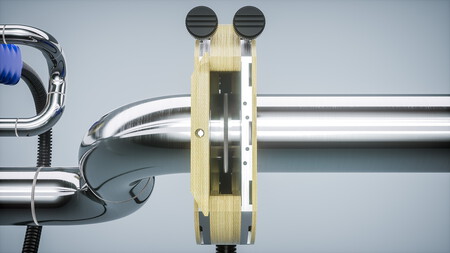

- Tube-to-tube joints

- Tube-to-tubesheet joints

- Tube-to-fitting joints

Orbital welding is used in the following industries and sectors, to name a few:

semiconductors, aerospace, pharmaceuticals, chemicals, food and beverage, shipbuilding, boilers and heat exchangers, oil and gas, petrochemicals and renewable energies.

There are also many other industrial applications where only orbital welding meets the necessary quality requirements.