PURGING

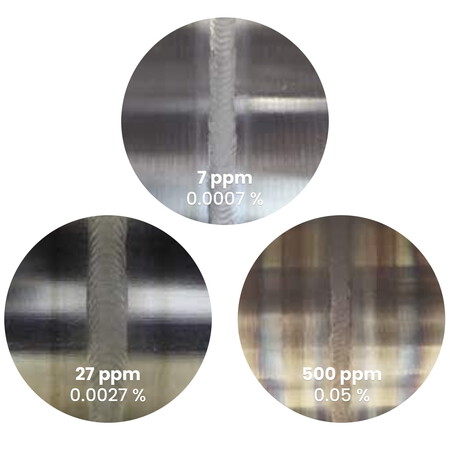

Proper purging is absolutely essential to guarantee high-quality welding of high-alloyed, corrosion-resistant components. Our Oxy EVO oxygen analyser can be connected to our orbital welding controllers for the purpose of inspecting and documenting the residual oxygen content and evaluated. You are free to choose the value in ppm entered in the controller.

Unless specified otherwise, a value < 30 ppm is generally sufficient for starting welding. The controller will not allow welding to commence until the measured value drops below the entered value. The equipment is calibrated so that it measures with an accuracy of +/- 2 ppm in the welding-related area below 30 ppm in the case of inert gases.

Analysers that display values as percentages are not recommended ➝ 0.1% = 1,000 ppm!

Accessoires de façonnage

Embout de tube pour la protection gazeuse

- Conique

- Perçage : Ø 6 mm | 0,236“

- Matériau : silicone, incolore

- Résistance thermique jusqu’à 250° C

Item number: 1.3.55+XX

Set d’embouts de protection gazeuse

Pour dia. int. 47 – 107 mm / 1,850” – 4,213” (9 x 2 embouts) en coffret

Item number: 1.3.5502

Set d’embouts de protection gazeuse

Pour dia. int. 10,5 – 49 mm / 0,413” – 1,929” (10 x 2 embouts) en coffret

Item number: 1.3.5501

Tuyau de protection gazeuse avec vanne d’arrêt, 8 m

Item number: 1.3.0126

Diffuseur en métal fritté

(Compatible avec les embouts en silicone avec perçage 6 mm à partir d’un diamètre intérieur de tube de 15 mm)

Item number: 1.3.0127

Chambres de gaz de protection

- Économie de gaz et de temps

- Résistance thermique jusqu’à 340° C

- Applicable dans toutes les positions

- Traction simple possible par les tubes coudés

SC Profi, monté complètement avec 2 lèvres d’étanchéité (340° C), axe de liaison et tuyau de raccord avec embout droit de type 21

Item number: 1.1.60+XXX

Cylindre de gaz de protection WS Plus

Item number: 1.1.6+XXX

Couplage chambre de gaz de protection/tuyau de protection gazeuse, dia. ext. 6 mm

Raccord de mesure de la chambre de gaz de protection sur OXY

(à partir de SC Profi Ø 57) sur demande

Item number: 1.1.6234

Ruban adhésif en aluminium

6 x 15 x 48 mm

Item number: 1.1.4129